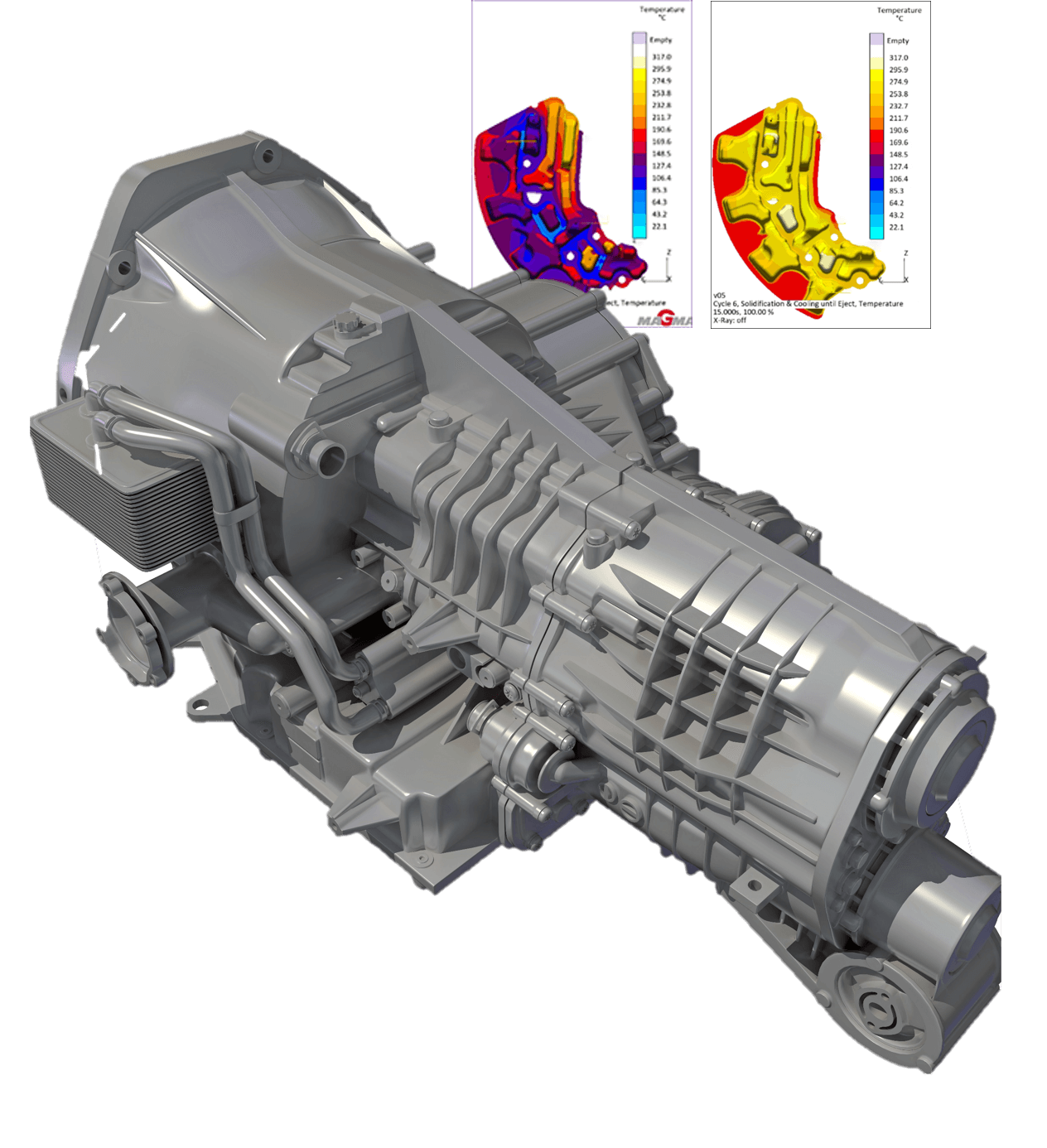

Automobile Transmission Housing

ASSAB Additive Manufacturing Solution

In the automotive industry, efficiency, durability, and performance are paramount. An essential component ensuring the seamless operation of vehicles is the transmission housing. It houses the transmission system responsible for transferring power from the engine to the wheels, ensuring smooth gear shifting and optimal vehicle performance. Given its critical role, the choice of material for manufacturing the transmission housing holds utmost significance. AM Dievar has demonstrated its ability to revolutionise the manufacturing process by notably enhancing tool longevity.

Traditionally, materials like 1.2709 have been the preferred choice for manufacturing transmission housings achieving the required mechanical properties. However, they often fall short in terms of tool life. The manufacturing process of transmission housings, involving high-pressure die casting, subjects the tooling to extreme conditions of heat, pressure, and wear, necessitating frequent tool replacements.

The game-changing solution lies in adopting AM Dievar, an advanced high-performance tool steel renowned for its exceptional durability and wear resistance. Replacing traditional materials such as 1.2709 with AM Dievar yield extraordinary results:

1. Tool Life Enhancement:

– A remarkable 200% increase in tool life compared to traditional materials.

– The production downtime caused by the frequent replacement of worn-out tooling was reduced significantly.

– Cost-effective as the manufacturing process became more efficient.

2. Consistency and Reliability:

– AM Dievar generated a higher yield of quality transmission housings.

– AM Dievar exhibited consistency which is a critical attribute in the automotive sector where minor variations can affect vehicle performance and safety.

3. Reduced Waste:

– Longer-lasting tooling results in fewer moulds and dies being discarded, thereby reducing the environmental impact of production.

– The automotive industry’s growing emphasis on sustainability is aligned with the adoption of materials like AM Dievar.

AM Dievar

AM Dievar is also an ideal choice for innovative design optimisation in automotive transmission housing production for the following reasons:

1. Complex Geometry: AM Dievar’s adaptability allows for the creation of intricate and complex mould designs. This is especially beneficial when designing transmission housings with intricate features such as the internal passages and cooling channels to improve overall functionality.

2. Weight Reduction: AM Dievar’s strength-to-weight ratio enables the design of lighter yet equally robust transmission housings. Reduced weight contributes to improved fuel efficiency and overall vehicle performance.

3. Temperature Control: AM Dievar’s superior thermal stability facilitates precise temperature control during the casting process. This helps in reducing defects like warping and ensures the transmission housing meets stringent quality standards.

Read more: Electrical Connector