Hot Stamping

Cold forming was the dominating method for making critical structural components in high strength steel. This has been supplemented by hot stamping, the new game-changing process which places new demands on the tool steel used in the process.

By using a heated blank that forms and hardens quickly in the die, parts can be made larger, stronger and more complex than before. This, however, places severe demands on the tool steel used in the dies. For instance, to function reliably at the temperatures required, the tool steel needs to have excellent thermal conductivity and hot yield strength as well as high toughness and ductility.

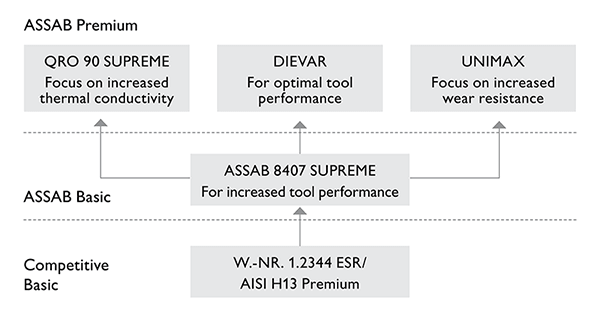

ASSAB’s tooling solutions for such exacting demands are several: QRO 90 Supreme, Unimax, Dievar and ASSAB 8407 Supreme. They all offer predictable tool performance, longer production runs, shorter cycle times and superior end products.