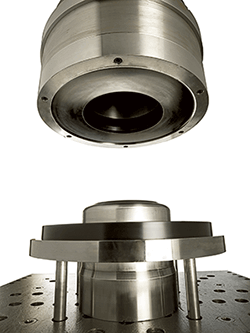

Cold Drawing

Cold drawing is the forming of a shell from a flat metal sheet into a shape that has side walls. Press drawing is normally referred to as deep drawing when the shape drawn is deeper than half its diameter. The ASSAB product portfolio offers a wide selection of cold work steels to reach cost efficient production and optimum productivity.

The tooling material selection is crucial. Due to cyclic mechanical loading and sliding contact between work material and tool surface, the active surfaces of the tool are successively damaged. The destruction of the tool will sooner or later lead to quality problems on the formed parts (out of tolerance or bad surface qualities). The tool has then to be exchanged (total failure), reground or refurbished in some way. Our industry experience shows that wear, chipping, plastic deformation, cracking and galling are the most common failure mechanisms.

The maintenance procedure means production standstill and accordingly loss of productivity. It is therefore very important that the tools can resist the different types of tool failure mechanisms in order to achieve high productivity and economical production. The selection of the right tool steel is thus directly linked to the resistance of the actual tool failure mechanism for the application. With this in mind we emphasise the importance of assessing the total tooling economy when selecting the right tool steel.