Machining

Unless equipped with the necessary tools and excess workspace, machining of tool steel can pose challenges and add disproportionately to your total tool production cost. That’s when partnering with ASSAB, your single service provider, makes economical sense.

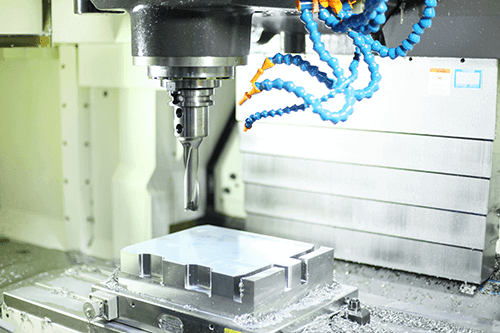

Our machining service provides value-add to a full range of steel grade solutions, from black steel to finished components. Machining we undertake includes milling, grinding, gun drilling, slotting, high speed machining and wire electrical discharge machining (WEDM).

ASSAB’s experience in delivering pre-machined steel plates goes back a long way. We offer a broad range of flexible customer-adapted machining solutions designed to aid your production processes and planning.

Of importance is our CNC Contour Machining Service which when coupled with our heat treatment service, can reduce a typical mould-making cycle by two days or more, an attractive proposition for time-critical industries like mobile phones and electronic sectors.

Pre-machining to exact specifications (dimensions, execution, steel quality, packing, marking and logistics) provides many advantages:

- Effective supply chain management and short delivery time

- Less material consumption and less tool wear

- Elimination of surface defects, flaws and cracks, and decarburisation

- Simpler and cleaner handling as chips stay at ASSAB

- Optimal machining parameters lead to minimum internal stress and distortion of the steel

- Lower setup and warehousing costs