AM Tyrax

Engineered for Durability and Surface Excellence in Moulding

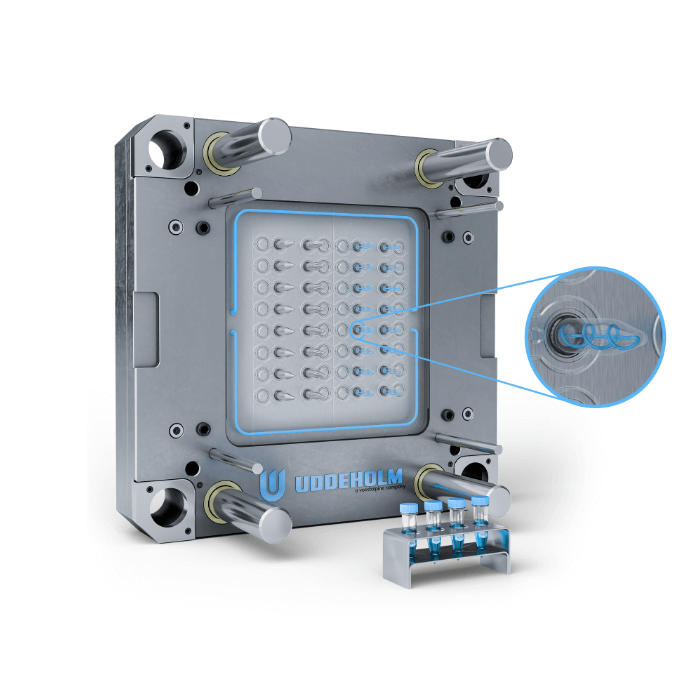

AM Tyrax is a next-generation stainless-grade powder developed specifically for additive manufacturing (AM), offering a significant advancement in tooling performance over conventional market-grade powders. It is engineered to meet the increasingly complex demands of industrial applications, particularly in plastic injection moulding, where durability, precision, and surface finish quality are paramount.

What distinguishes AM Tyrax is its balanced combination of hardness, wear resistance, corrosion resistance, mechanical toughness, and superior polishability. This unique synergy of properties directly addresses the limitations of many other existing AM powders. As manufacturers seek longer tool life, higher productivity, and reduced maintenance, the need for robust materials capable of withstanding harsh environments, including exposure to corrosive, fire-retardant plastics like PVC and PC, has become increasingly important. The requirement for high polishability poses a significant barrier for most additively manufactured (AM) parts.

Optimized Composition and Proven Performance

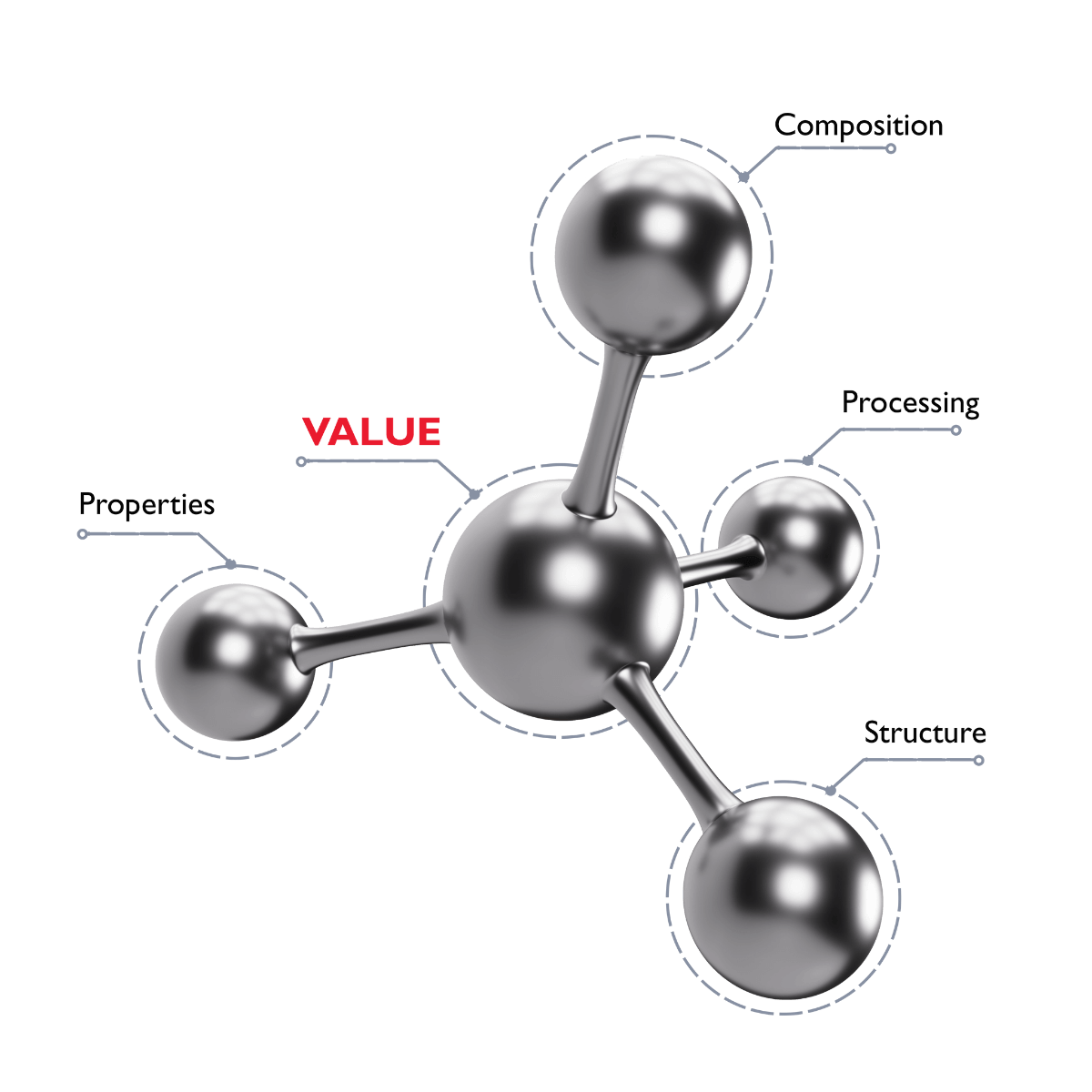

AM Tyrax has identical chemical composition as Tyrax ESR but is specifically optimized for additive manufacturing (AM). The performance of AM-printed parts is governed by four critical factors—material, processing, structure, and properties—which together form a “performance pyramid.”

When processed under optimized conditions, AM Tyrax parts can achieve:

- Density exceeding 99.995%

- Hardness up to 55 HRC

- Charpy V-notch impact toughness of 20 Joules after tempering

These outstanding mechanical properties make AM Tyrax one of the most advanced and reliable powders for producing high-performance mould inserts and components.

Exceptional Surface Finish and Polishability

AM Tyrax has been validated by customers to consistently achieve an A0 surface finish, meeting the highest industry standards. These results are attainable using standard post-processing techniques.

In addition, ultra-fine CNC finishing has demonstrated surface roughness values as low as 4 nm (Ra), making AM Tyrax exceptionally well-suited for optical and medical applications, where surface precision is critical.

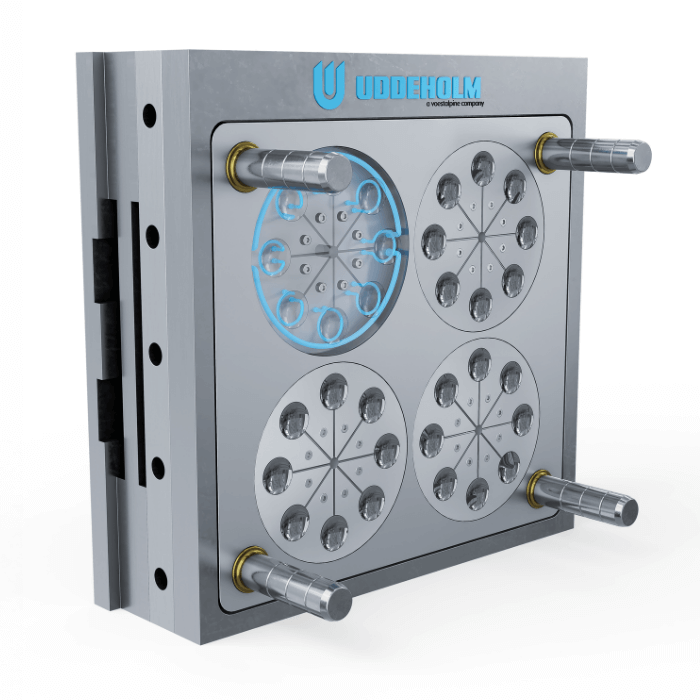

Superior Alternative to Nickel-Plated Inserts

AM Tyrax offers a compelling alternative to nickel-plated inserts, which are commonly used in lens moulding but suffer from limited tool life (<20,000 cycles) and require frequent replating and refinishing. In contrast, AM Tyrax provides higher hardness, enhanced wear resistance, and longer service life, resulting in significant cost savings and reduced downtime.

Tailored Solutions for High-Performance Applications

AM Tyrax delivers exceptional hardness and superior wear resistance, dramatically reducing production costs.

Whether you’re looking for a dependable balance of hardness and toughness with our standard grade treatment or aiming for ultra-high polishability with our premium grade, AM Tyrax ensures top-tier performance across a wide range of applications.

Its adaptability to diverse tooling requirements makes AM Tyrax a versatile, high-value solution for the future of precision moulding and advanced manufacturing.

For medical and industrial applications where both surface precision and material durability are essential, AM Tyrax offers a distinctive solution. Specifically developed for additive manufacturing, it is the only powder known to combine exceptional polishability with high hardness, wear resistance, corrosion resistance, and mechanical toughness in a single material.

AM Tyrax consistently achieves surface roughness values as low as 4 nm Ra and A0-grade finishes using standard post-processing techniques. These capabilities are particularly valuable in the production of high-precision moulds for optical parts, medical devices, and other demanding applications where surface quality directly impacts performance.

In comparison to other AM powders, AM Tyrax delivers a unique balance of properties that enables longer tool life, lower maintenance requirements, and reliable performance in challenging manufacturing environments.