Power up for a Reliable Storage

Vanadis 4 Extra SuperClean

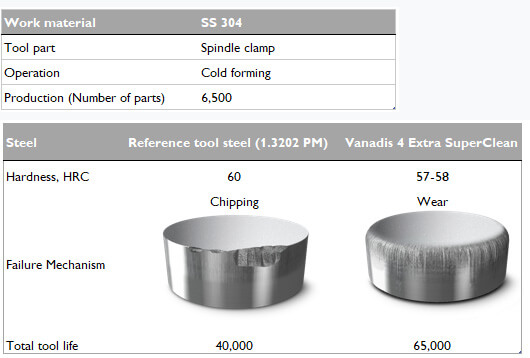

In the manufacturing of hard disk drive (HDD) spindle clamp, the choice of die steel is a critical factor that profoundly influences the final product’s quality and performance. Opting for Powder Metallurgical steel, Vanadis 4 Extra SuperClean in the cold forming process of spindle clamp is a strategically sound decision for the following compelling reasons:

Mechanical Resilience: HDD spindle clamps face substantial mechanical stresses and vibrations during operation. Vanadis 4 Extra SuperClean stands out by offering an exceptional combination of high wear resistance and ductility. This unique blend ensures that the tool maintains consistent performance when tackling the demanding cold forming process for HDD spindle clamps, safeguarding precision and reliability.

Dimensional Stability: The dimensional stability of Vanadis 4 Extra SuperClean is pivotal in HDD spindle clamp production as it directly influences precision, consistency, data integrity, performance, and the overall quality of the hard disk drives. Maintaining precise dimensions is indispensable to meet the rigorous requirements of the HDD industry, ultimately assuring effective data storage and retrieval.

By selecting Vanadis 4 Extra SuperClean for your cold forming spindle requirements, you are making a strategic investment in quality, precision, and reliability. This choice elevates your HDD production to meet and exceed the industry standards for performance, longevity, and precision, assuring a superior and dependable end product.

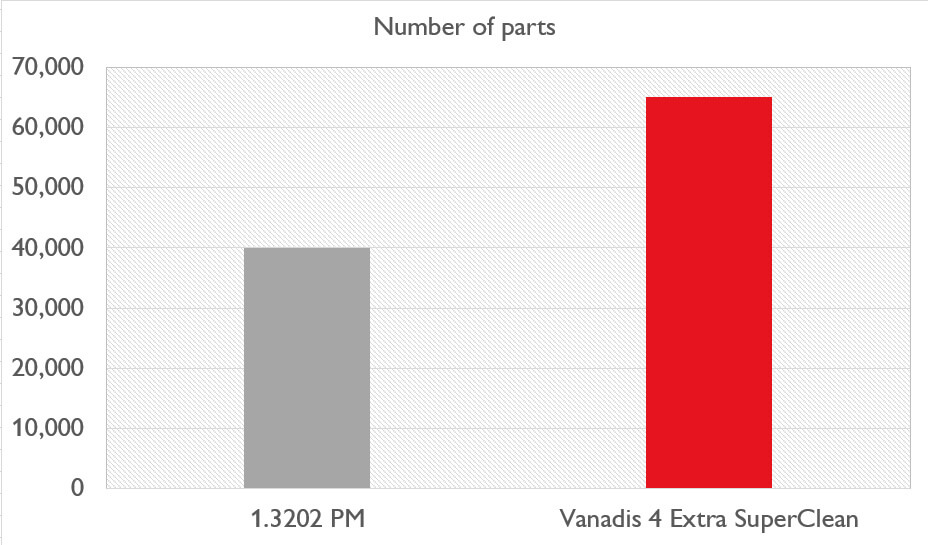

What Vanadis 4 Extra SuperClean helped to achieve:

Click here to consult about Vanadis 4 Extra SuperClean.