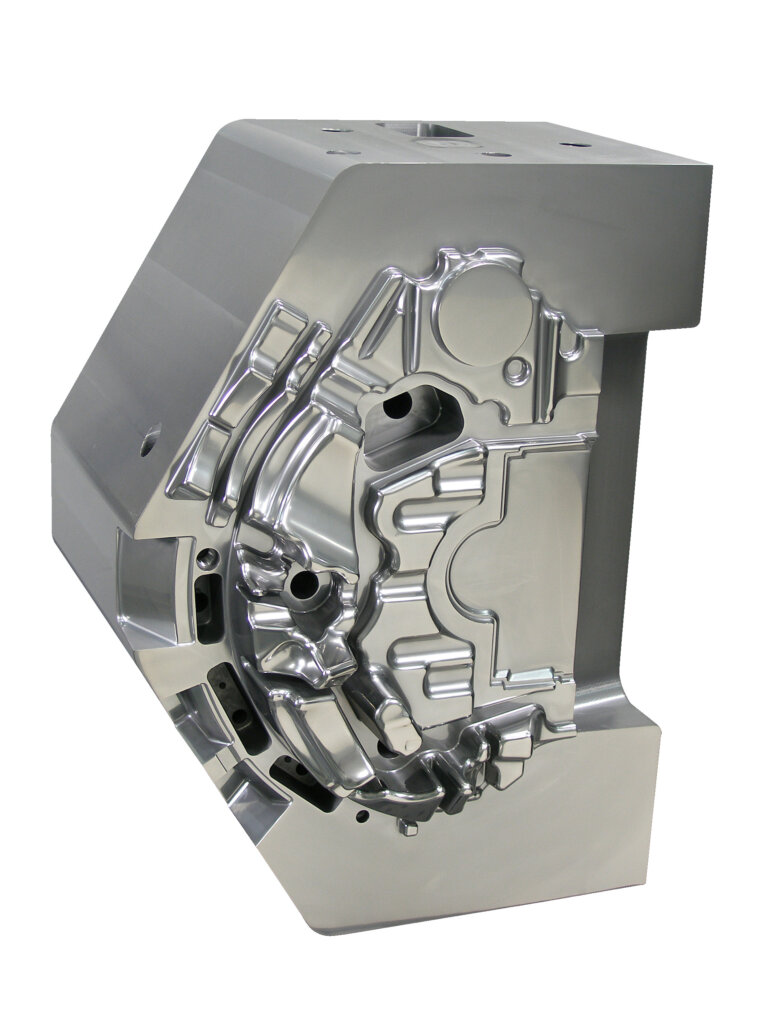

Duplex-TIGRAL: The Proven Armor for Your High Performance Die Casting Tools

Eliminate downtime. Extend tool life. Deliver top-quality parts.

In the competitive world of high-pressure die casting (HPDC), every production interruption, scrap part, or premature tool failure impacts your bottom line. Die casters constantly struggle with challenges such as erosion, thermal fatigue, cracking, soldering, abrasive wear, and excessive maintenance. These issues not only drive up operational costs but also reduce machine availability and throughput.

At ASSAB, we understand these pain points because we work closely with leading toolmakers and foundries across the globe. Our WHY is simple: to help our customers produce more, with better quality, while spending less on tool maintenance and replacements.

Duplex-TIGRAL was developed by eifeler, a sister brand of ASSAB, precisely to serve this mission — enabling your tools to endure longer cycles under extreme thermal and mechanical loads while maintaining consistent part quality.

How Duplex-TIGRAL Solves Your Challenges

An advanced coating system built for today’s extreme HPDC applications.

Duplex-TIGRAL is not just a coating; it is a multi-stage surface engineering solution combining plasma nitriding and an advanced nano-structured AlCrTiN matrix layer. The result is a synergistic effect that fundamentally enhances the mechanical and chemical durability of your HPDC tooling.

The Duplex Advantage:

- Plasma Nitriding (zero white layer): Prepares the substrate by increasing surface hardness, compressive strength, and hot hardness — while preserving a homogeneous hardness profile. This layer improves adhesion of the PVD coating, prevents subsurface plastic deformation, and provides strong support under thermal cycling.

- AlCrTiN Nano-structured Matrix: Offers superior resistance to abrasion, erosion, oxidation, and chemical attack at temperatures up to 900°C (1650°F). Its nano-structure inhibits crack propagation — especially under high shear stresses common in HPDC.

The Unique Chemistry of Duplex-TIGRAL

- Minimizes soldering (prevents aluminum alloy from sticking to the die surface), resulting in superior release properties and significantly lower demolding forces — even after extended production runs.

- Retards fire cracks and thermal fatigue through optimized thermal stability and excellent oxidation resistance, ensuring stable performance under extreme cyclic loading.

- Reduces erosion caused by molten metal flow, die lubricants, and casting dynamics, protecting critical tool areas.

- Prevents alloying attack and adhesive wear, maintaining smooth tool surfaces and enabling consistent, trouble-free part release.The outcome: longer tool life, lower scrap rates, fewer unplanned maintenance interventions, and improved productivity.

What Duplex-TIGRAL Delivers

Proven technical results you can rely on.

| Coating material | AlCrTiN |

| Micro-hardness (HV 0.05) | 3300 ± 300 |

| Coefficient of friction | 0.6 |

| Coating thickness | 3–5 μm |

| Max service temperature (coating) | 900°C (1650°F) |

| Color | dark grey |

| Nitriding process temp. | max 500°C (925°F) |

| Compatibility | Advanced hot work and cold work tool steels |

| Application range | HPDC dies, cores, inserts, forming dies, complex tools |

Duplex-TIGRAL is fully compatible with the most advanced hot work and cold work tool steels produced by leading steelmaker such as Uddeholm— including steels with high thermal conductivity, high toughness, and resistance to thermal fatigue — ensuring the coating works synergistically with modern tool substrates. Welded tools and repair-welded substrates can also be successfully coated.

Key Benefits for Die Casters:

- Increased tool life

- Lower tool maintenance and downtime

- Reduced production costs

- Enhanced part quality & surface finish

- Improved part release — Lower demolding forces

- Repeatable coating process — tools can be stripped and recoated multiple times

- Preserves dimensional tolerances — No distortion

Why Duplex-TIGRAL Drives Real Value for Your Die Casting Operation

By adopting Duplex-TIGRAL, you move from a reactive maintenance approach to a proactive tooling strategy:

- Experience predictable, extended tool performance, reducing the risk of costly, unplanned downtime.

- Produce parts with consistent quality and surface finish, minimizing scrap and rework.

- Gain cost advantages by maximizing tool service life while cutting maintenance hours and interventions.

- Strengthen your competitive edge with proactive process stability that delivers higher productivity and on-time delivery performance.

That is why leading die casters and OEM suppliers rely on Duplex-TIGRAL to optimize their production — not just for today’s challenges, but for the long-term performance and profitability of their HPDC lines.

Unmatched Expertise Across the Entire Value Chain

When choosing Duplex-TIGRAL, you benefit not only from an advanced coating — but from the unmatched expertise of ASSAB, the market leader in tool steel, heat treatment, surface preparation, and PVD coatings. Our team of specialists supports you throughout the full supply chain: from selecting the optimal tool steel to defining the right heat treatment, to delivering precise pre- and post-polishing services tailored to your application requirements. No other supplier in the market can offer this integrated expertise — ensuring that every step in your tooling process is optimized for maximum performance, tool life, and cost-efficiency.

READ MORE: Surface Coating