Blow moulding

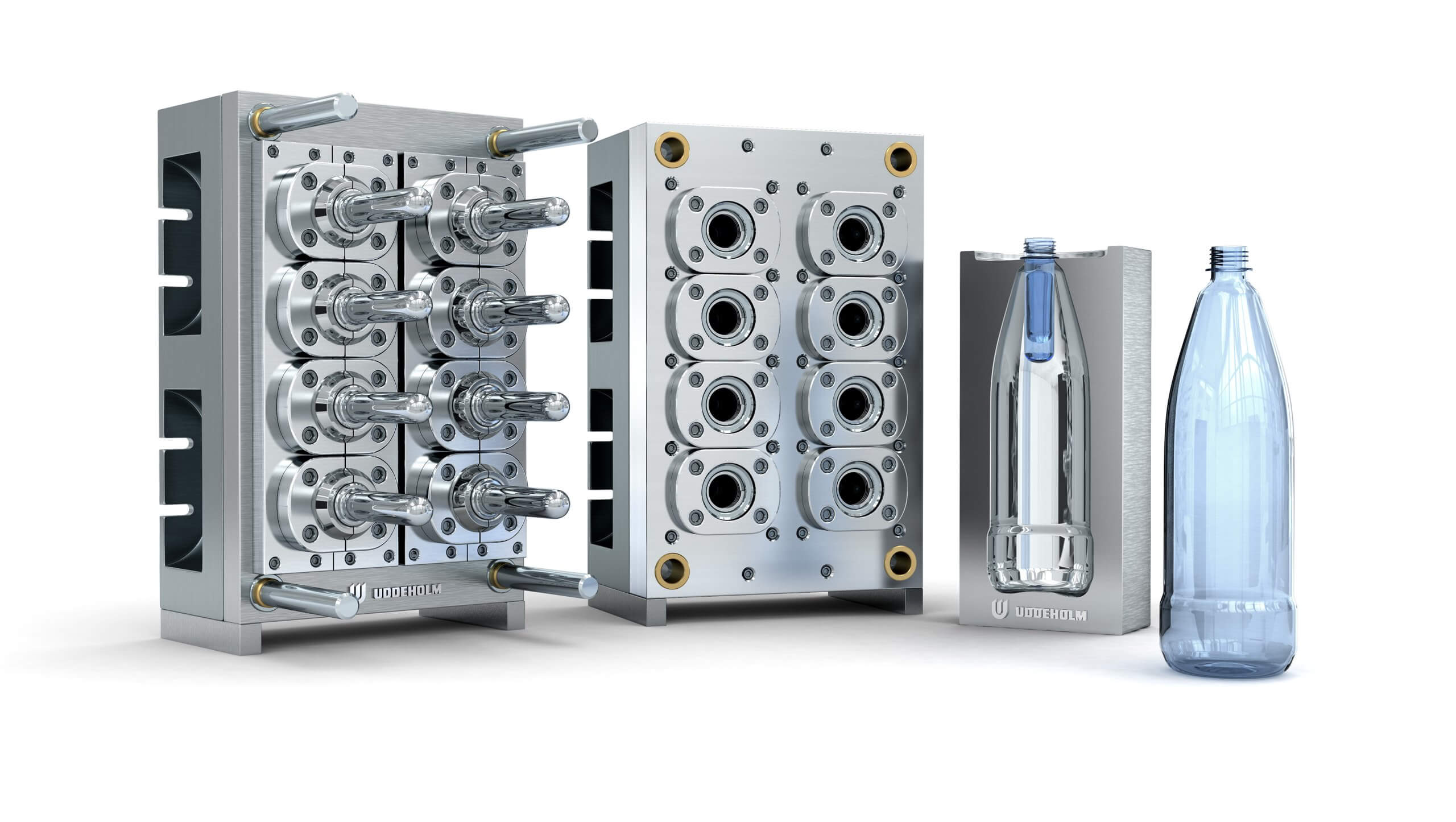

There are different methods for blow moulding, a process for shaping a hollow product by stretching a hot thermoplastic tube with air pressure and cooling it against a mould surface.

Blow moulding, in general, is a low pressure method where strength and wear demands are moderate, and a high productivity process where cycle time are of great importance. Corrosion is also a potential risk due to the common use of PVC especially in the production of bottles.

Consequently, important mould steel properties for blow moulding are moderate strength and wear demands, good heat conductivity and high corrosion resistance.

ASSAB’s answer for this application includes pre-hardened materials like ASSAB 718, Nimax, Mirrax 40, Coolmould, Al alloys and through-hardened steel such as Stavax ESR and Mirrax ESR depending on requirement for wear and indentation resistance as well as plastic material.