Forge the Future: Precision Heat Treatment & PVD Coating for Giga Casting Dies

In the dynamic and rapidly evolving electric vehicle (EV) industry, the efficiency and reliability of giga casting dies are critical. These massive tools are crucial to EV production, and we understand their pivotal role. Our expertise in vacuum heat treatment, surface treatment, and PVD coating ensures that your giga casting dies deliver outstanding performance, maintaining reliability and efficiency over tens of thousands of cycles.

Why Our Expertise Matters

Our engineers at ASSAB possess unparalleled expertise in understanding the properties and behaviours of tool steel during heat treatment. We work closely with you to select the optimal steel grade, precisely tailored to your specific casting materials, pressure demands, and desired cycle life.

Precision Heat Treatment for Superior Die Performance

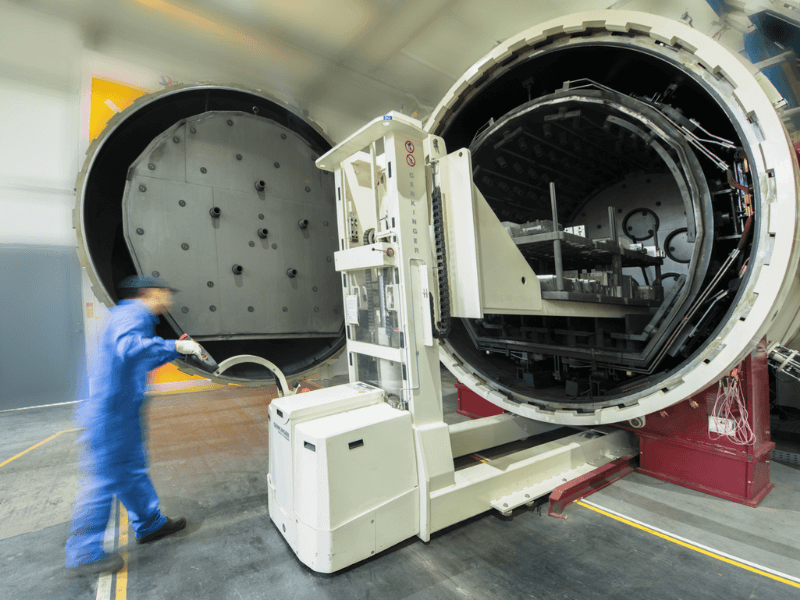

Our cutting-edge vacuum heat treatment furnaces provide precise control over temperature, vacuum, and gas quenching processes. This meticulous approach ensures uniform heating, hardening and minimises distortion, crucial for maintaining the structural integrity and functionality of your dies. Key benefits of our processes include:

- Enhanced Surface Wear Resistance: By enhancing the die’s resistance to surface wear, our treatment helps to maintain the die’s precision and performance over extended operational periods.

- Minimised Heat Checking: Our precise control over the heat treatment process minimises the development of heat checking and soldering issues. This reduction leads to a more reliable die surface which is essential for producing high-quality castings without defects.

- Improved Surface and Core Toughness: Our process not only improves surface toughness but also reinforces the core, providing a balanced toughness profile. This dual enhancement is critical for withstanding the rigorous demands of high-cycle operations and maintaining consistent casting quality.

Our state-of-the-art vacuum heat treatment delivers exceptional durability and performance, ensuring your giga casting dies meet the required standards of quality and longevity.

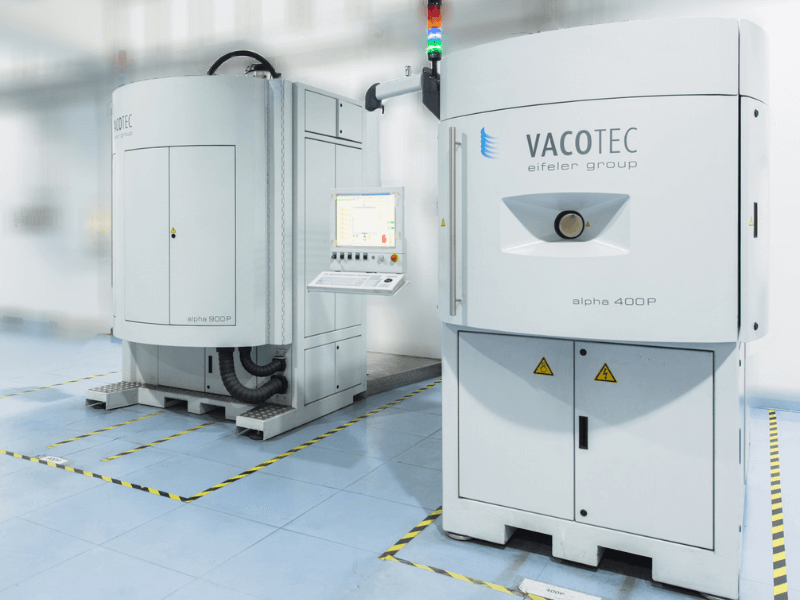

Advanced Surface Treatments and Coatings for Optimised Performance

At ASSAB, we go beyond the boundaries of heat treatment. We offer a comprehensive suite of surface treatments such as ABP and ABP Plus, and PVD coatings specifically designed for giga casting dies. Our advanced coatings, such as TIGRAL and VARIANTIC, provide substantial improvements in performance areas such as:

- Enhanced Wear Resistance: Our coatings dramatically extend the lifespan of your dies by minimizing surface wear caused by molten aluminium. This longevity ensures your dies maintain their functionality and precision over extended periods, reducing the need for frequent replacements and maintenance.

- Reduced Friction: By lowering the coefficient of friction, our coatings facilitate smoother casting processes. This improvement not only enhances the quality of cast parts but also minimizes soldering issues and boosts energy efficiency, contributing to more sustainable and cost-effective operations.

- Increased Thermal Stability: Our coatings significantly increase the die’s resistance to thermal fatigue, crucial for withstanding the stress from repeated heating and cooling cycles. This stability preserves the die’s structural integrity under intense operational conditions, ensuring consistent performance and longevity.

Partner with ASSAB for Unmatched Giga Casting Die Solutions

When you partner with ASSAB, you gain access to unparalleled expertise and a steadfast commitment to quality:

- Unmatched Expertise: Leverage our deep knowledge of tool steel, heat treatment, surface treatment, and PVD coating for giga casting applications.

- Customized Solutions: We collaborate closely with you to develop a treatment plan specifically designed to meet your unique die requirements.

- Rigorous Quality Control: Our unwavering commitment to quality ensures consistent performance and extends the lifespan of your valuable dies.

Choose ASSAB for exceptional durability, efficiency, and performance of your giga casting dies, even in the most demanding environments.